Hydraulic Lift Upgrade

We perform hydraulic lift upgrades

A hydraulic elevator is a type of elevator that uses a hydraulic system to move the lift car up and down. They were installed in many buildings with a typical height of six floors or less. If you need a Hydralic Lift Upgrade, we can definately help!

How It Works

A hydraulic elevator operates by using a hydraulic fluid, usually oil, which is pressurized by an electric pump. This pressurized fluid is then pushed through a valve block and into a cylinder, causing a piston to move and lift the elevator car. To lower the car, the fluid is released back through the system into the tank, allowing the car to descend smoothly

Main Components

1. Hydraulic Pump/Motor: Located fully or partially inside a tank, this component pressurizes the hydraulic fluid or oil.

2. Valve Block: Regulates the flow of hydraulic fluid from the tank through the main hose to the RAM.

3. Hydraulic Rupture Valve: Positioned at the base of the RAM, this safety device, also known as an overspeed valve or pipe rupture valve (PRV), prevents the elevator from moving too fast or crashing if the hydraulic line breaks.

4. Cylinder – Houses the piston and receives the pressurized fluid.

5. Piston – Moves within the cylinder to lift or lower the elevator car.

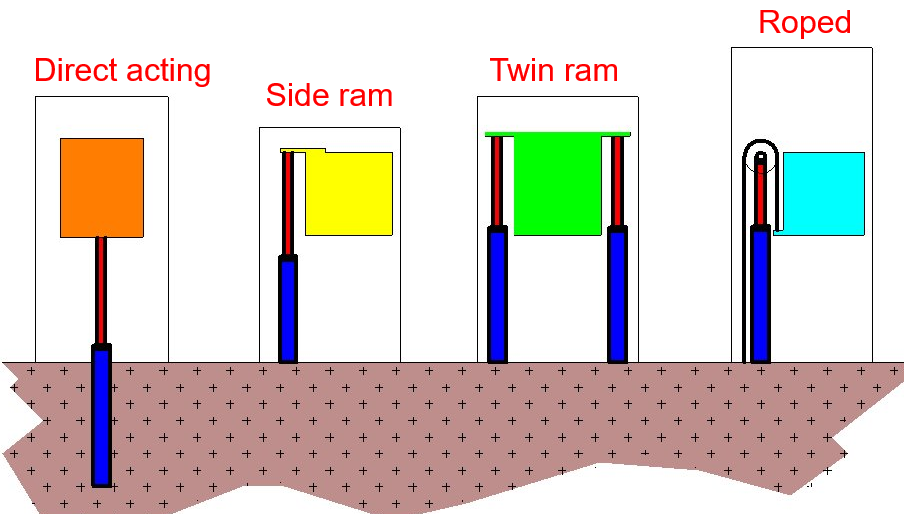

There are generally four types of hydraulic elevator arrangements

The typical lifespan of a hydraulic elevator is 15-20 years. At this point, upgrades should be considered to ensure the elevator remains operational and reliable.

We can perform a hydraulic lift upgrade to refresh the life of your lift and improve safety compliance.

Old Hydraulic System

Over time, hydraulic systems experience wear and tear due to the continuous pressurized flow of fluid from the tank to the RAM. As a result, motors and pumps can become old and noisy, valve blocks may wear down internally, and RAM seals can start to leak. These leaks in valve blocks and RAMs cause pressure issues, putting additional stress on the controller and motor, leading to constant releveling. This frequent releveling heats up the oil and significantly increases energy consumption.

New Hydraulic Tank System

The most effective upgrade for any hydraulic lift is to completely replace the tank, motor, and pump system. This new system significantly alters the operational characteristics. The motor is positioned outside the oil and is controlled by a variable frequency (VF) drive, ensuring more precise operation of the pump system.

This upgrade package drastically reduces energy consumption and provides smoother, more controlled operation. It also operates much cooler, which extends the lifespan of the equipment.

We can inspect your hydraulic lift and provide recommendations.

When considering a hydraulic lift upgrade, there are generally two options.

Basic Upgrade

Features

-

New Controller with Soft Start

-

New Valve Block

-

New Hydraulic Oil

Major Upgrade

Features

-

New Controller with VF Drive

-

New Valve Block

-

New Hydraulic Oil

-

New RAM Seals

-

New Tank, Motor & Pump

-

Reduced Energy Consumption

-

More Controlled Movement

Why would I need a Hydraulic Lift Upgrade?

Hydraulic systems, like all mechanical equipment, will suffer from wear and tear with age. Parts eventually start failing to deliver the reliable and consistent operation that should be expected. There are many reasons why you should consider upgrading.

➤ Obsolescence. The existing valve block and controller may be obsolete with replacement parts no longer manufactured. This leaves a risk to the owners of extended downtimes if important components fail.

➤ Poor Operation & Age. Old hydraulic lifts can lose their ability to control the pressurized oil flowing from the tank to the RAM. Pressure issues in the system can lead to constant releveling operations involving the controller, motor, and pump. This results in overheated and burnt oil, which produces an unpleasant smell for passengers. Additionally, the tank becomes very noisy, and leveling issues can create trip hazards. Old lifts may also shake during takeoff and slowdown, leaving a poor impression on visitors.

➤ Improved Performance. Hydraulic systems typically have a lifespan of 15-20 years before problems begin to emerge. The controlled operation of the elevator reassures passengers about its overall reliability. It’s crucial to maintain reliable, controlled, and consistent elevator performance. Upgrading your hydraulic lift will ensure dependable service and mitigate the risk of eventual failure.

Frequently Asked Questions

If the major hydraulic upgrade is performed, along with the door system and button fixtures, we would expect another 20 years of operation.

We perform alot of hydraulic lift upgrades every year with great success.

A VF drive provides more precise control of the pump system, leading to an improved ride quality, reduced energy consumption, and less wear and tear on components.

Yes, modern hydraulic systems are designed to operate more quietly. Replacing old components can significantly reduce noise levels.

Yes, it is possible to completely replace a RAM. However, most of the time it is not possible to get a new RAM into the lift shaft as they were installed during the original construction of the building.

We do not replace complete hydraulic RAMs.

If a RAM becomes scorched/damaged, it is more cost effective to explore a full lift repalcement as an option. Often it is more cost effective to completely replace the lift, than to replace the complete RAM. To know if your RAM has reached the end of its life, replacing the RAM seals will not stop the oil from leaking and pressure issues arising.

We assess the hydraulic RAM during our inspections. When we see hydraulic oil in a pit, it outlines that the RAM seals need to be replaced.

No. The ride quality will be improved and more controlled, however most hydraulics will never be perfectly smooth compared to a traction elevator.

Additionally, most or all hydraulic upgrades retain the original RAM which does add a level of resistance when the hydraulic system is pressurizing to drive.

Yes, a modern and reliable lift can enhance the overall value and appeal of your property, making it more attractive to tenants and visitors.

Ask US! We can inspect your lift equipment and provide valuable information about what exists and what future planning may be required.

Basic upgrades work great and include upgrading the controller and valve block on top of your tank. This type of upgrade retains your tank, motor and pump in the machine room. We mainly recommend Blain Valve Blocks –> BLAIN WEBSITE

Lets Talk