Lift Machine Upgrade

What is a lift machine?

A lift machine is a key component of an elevator system that powers its movement. Its primary purpose is to raise and lower the elevator car between floors. The machine is typically located in the elevator’s machine room or inside the lift shaft at the top.

Here’s a breakdown of how it works:

Drive Mechanism: The lift machine uses a motor (usually an electric AC motor) to drive a system of pulleys and cables. The motor turns a sheave that moves the lift ropes or belts, which are connected to the elevator car and counterweight. This system allows the elevator to be raised or lowered smoothly.

Counterweight: The counterweight helps balance the weight of the lift car, making it easier for the machine to lift the car. This reduces the amount of energy needed to move the elevator, improving efficiency.

Safety: The machine plays a crucial role in the safety of the elevator. It includes features like brakes, secondary brakes, upward runaway protection, and limit switches to prevent accidents by ensuring the elevator does not move too quickly, erratically or unplanned.

The lift machine is important because it directly affects the ride quality, efficiency, and safety of an elevators operation. It is vital for controlling the speed, capacity, and reliability of the system, especially in taller buildings where high-speed or high-capacity elevators are needed.

This page explains why a lift machine upgrade should be proactively considered.

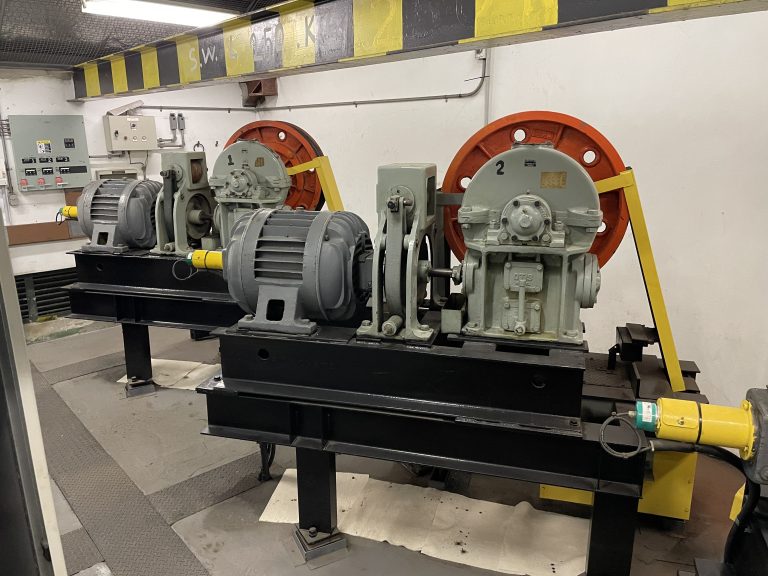

Old Lift Machines

These are some examples of old lift machines. The machine is vital to the safety and operation of every elevator. Old machines may not comply with secondary brakes or guarding. Some machines become obsolete with no replacement parts available and overtime become worn requiring replacement.

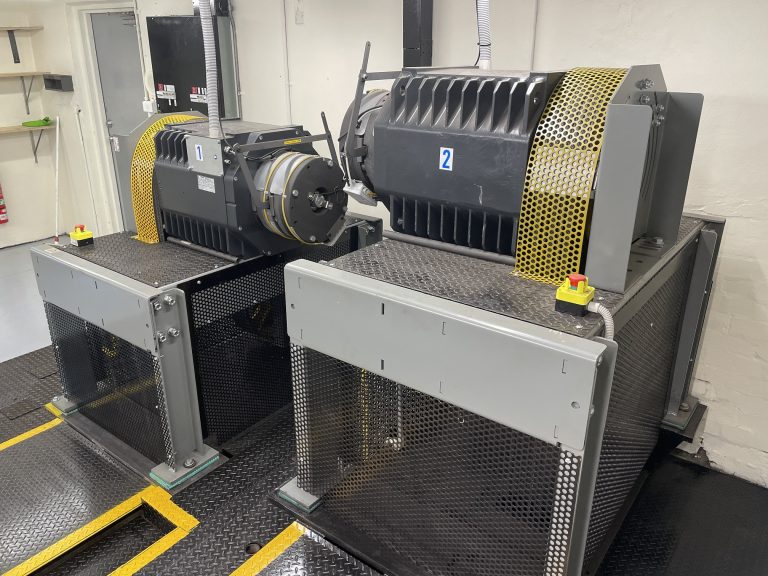

New Lift Machines

Lift Machine Upgrade Photos.

New machines installed to improve ride quality, improve safety compliance and remove the risk of failure. It is important to proactively plan to keep your lift operational, reliable and safe.

Below are examples of commonly used machines.

We only use high quality products that are commercially available.

The type of machine used depends on what will adapt to your existing elevator.

Lift Equip

A large range of geared and gearless elevator machines to provide compliant solutions for modernisations and new installations. Manufactured in Germany and used all over the world.

Ziehl-Abegg

High quality range of lift components including machines and speed drives for all elevator applications. Manufactured in Germany and used all over the world.

Why would I need to upgrade the lift machine?

The lift machine is used during every operation of the lift. It is vital that the machine is operating safely without risk to passengers. There are many reasons why you may need to upgrade your lift machine.

➤ Obsolescence. The existing machine may be obsolete with replacement parts no longer manufactured. Over time these machines do wear and do require parts being replaced. This leaves a risk to the owners of extended downtimes if the machine components fail.

➤ Poor Operation & Age. The life expectancy of an elevator machine is dependent on numerous factors that include the usage frequency of the lift, the quality of the installed equipment, the type of lift application and the age of the equipment. Typically, as the lift machine ages with millions of uses the ride quality starts to become rough/bumpy, oil may leak, brake issues may start causing the lift to shutdown and power issues may cause the speed drive to fault.

➤ Improved Performance. Generally, lift machines have a life expectancy of 20-25 years before issues start to arise. The smooth operation of the elevator instills confidence in passengers regarding the elevator as a whole. Ensuring that the elevator operation is smooth, controlled, and consistent is essential. Upgrading the lift machine will ensure the ride quality is improved, and removes the risk of eventual failure.

Frequently Asked Questions

It is in the owners best interest to eliminate risks associated with lifts breaking down or failing. Typically, if the machine is 20 to 25+ years old or obsolete, an upgrade should be considered.

No, we do not recommend this. Elevator machines are custom-built for each site and should be promptly installed once delivered. Keeping a new machine idle for an extended period may nullify the warranty. It is advisable to complete any lift machine upgrade project in a single stage for optimal efficiency and performance.

Safety compliance upgrades should be considered while upgrading the machine. These may include machine room lighting improvements, LED strip shaft lighting, emergency stop switches in the shaft/machine room & top of car equipment.

Ask US! We can inspect your lift equipment and provide valuable information about what exists and what future planning may be required.

Lets Talk